Quality Control in Feed Manufacturing Process

Introduction

Animal feed is a cornerstone of livestock production, directly influencing animal health, productivity, and ultimately the quality of animal-derived foods for human consumption. Ensuring that manufactured feed meets consistent nutritional and safety standards is critical, not only for livestock performance but also to protect public health and meet regulatory requirements. Quality control (QC) in feed manufacturing encompasses all systematic procedures that guarantee ingredients and final products adhere to predefined standards. From raw material inspection to finished-product testing, an effective QC program minimizes risks associated with contamination, nutrient variability, and process inefficiency while fostering consumer confidence in animal products (Richardson, 1996;Medion, 2025).

Quality Control Managemen

Key Goals of Quality Control

The primary objective of QC in feed manufacturing is to ensure that each batch of feed consistently meets nutrient specifications, is free of harmful contaminants, and provides the intended animal performance benefits. This involves inspecting raw materials, controlling the manufacturing process, and testing finished products. Moreover, the Quality control management serves as the backbone of a feed mill’s operational integrity and commercial success. A comprehensive program typically includes specifications for ingredient acceptance, critical control points within production, periodic sampling, laboratory analyses, and process documentation (Feedstuffs, 2025; RICHI, 2025).

Raw Material Inspection and Supplier Evaluation

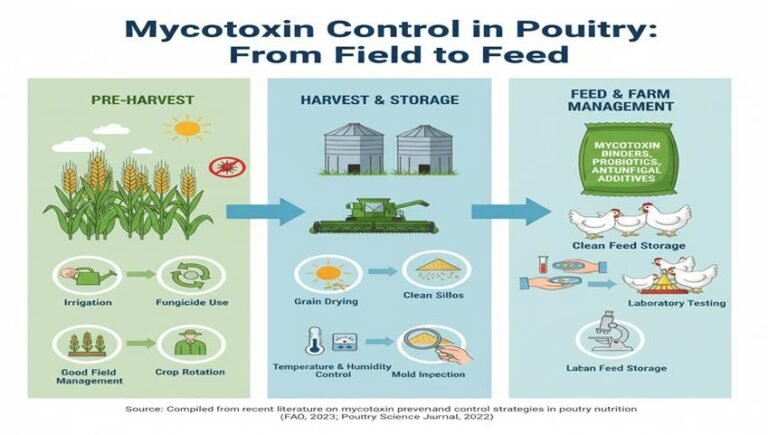

Because the quality of final feed is heavily dependent on the quality of raw materials, rigorous inspection and acceptance protocols are crucial. Incoming grains, protein meals, vitamins, and minerals should be sampled and analyzed for mycotoxins, moisture, protein content, and other key factors. Regular supplier performance evaluations support consistency; suppliers demonstrating frequent deviations should be reviewed or replaced. Written sampling procedures and standardized inspection checklists help ensure consistency in material quality analysis.

Process Control and Monitoring

Once raw materials pass inspection, the manufacturing process must be tightly controlled. Feed mills typically implement standard operating procedures (SOPs) for grinding, mixing, pelleting, cooling, and packaging. Key process parameters such as particle size, temperature, and moisture content are continuously monitored to ensure product uniformity. Quality control teams often use statistical process control (SPC) charts to detect shifts in process trends before they escalate into major issues. This proactive approach reduces variability and waste by enabling timely corrective actions.

Finished Product Testing

Final product evaluation is the culminating phase of QC management. Finished feeds are tested for nutrient composition, pellet durability, and absence of contaminants. Advanced techniques such as Near-Infrared Reflectance (NIR) spectroscopy and microbiological screening are frequently employed for rapid, accurate results. Only products that meet all internal specifications and regulatory compliance requirements are approved for distribution. Regular audits, staff training, and participation in external proficiency testing bolster internal confidence in testing reliability.

Fig: Quality Control in Feed Manufacturing Process

Documentation and Traceability

A robust QC system includes meticulous documentation of all tests, inspections, and corrective actions taken during the manufacturing cycle. Traceability systems that link raw materials to finished products support transparency and enable rapid response during recalls or customer complaints. Comprehensive records provide evidence of due diligence and support compliance with food safety standards such as ISO 22000 and HACCP-based systems.

Recent Trends in Quality Control

Data-Driven Monitoring and Business Intelligence

Modern quality control is increasingly driven by data analytics and business intelligence (BI) systems that provide real-time visibility into production performance. These platforms aggregate sensor data from across production lines, enabling managers to monitor key performance indicators (KPIs) such as moisture variation, ingredient consistency, and equipment uptime. By leveraging big data analytics, trends can be identified ahead of time, and predictive insights can avert process deviations before they impact product quality. Integrating BI has transformed QC from a reactive to a proactive discipline.

Artificial Intelligence (AI) and Predictive Analytics

AI integration into QC systems is one of the most transformative trends in feed manufacturing. Machine learning algorithms can identify subtle patterns within complex datasets that elude traditional analysis. By analyzing historical production data, these models can forecast when a parameter is likely to drift outside control limits, allowing pre-emptive intervention. Predictive analytics reduces downtime, optimizes resource usage, and enhances overall product stability.

Internet of Things (IoT) and Real-Time Sensor Networks

IoT devices are proliferating on factory floors, providing continuous, high-resolution data streams from mixers, pellet presses, and storage environments. These sensors make it possible to track humidity, temperature, and equipment performance in real time. IoT ecosystems improve traceability and early detection of anomalies, ensuring that deviations are quickly surfaced and mitigated, ultimately strengthening QC practices across the facility.

Automation and Laboratory Integration

Automation in laboratory workflows enhances the speed and reliability of feed analysis. Automated sample processing and reporting systems eliminate many manual steps, reducing human error and allowing laboratory technicians to focus on complex interpretation and quality strategy development. Seamless integration of lab results with production data improves feedback loops and closes the gap between testing and operational decision-making.

Conclusion

Quality control in feed manufacturing is a multifaceted discipline that underpins the reliability, safety, and nutritional value of animal feeds. Effective QC management begins with stringent raw material inspection, extends through process control mechanisms, and culminates in comprehensive finished-product testing and documentation. Emerging trends—such as advanced data analytics, AI-driven predictive models, and IoT-enabled real-time monitoring—are reshaping how quality is ensured, making modern QC more proactive and resilient than ever before. As demand for high-quality feed continues to grow alongside technological innovation, the future of quality control will increasingly rely on integrated digital systems that strengthen decision-making, optimize operations, and safeguard animal and public health.

References

Feedstuffs. (2025). Quality control program without quality assurance can be costly. Retrieved from industry source.

Medion. (2025). Importance of feed quality control. Retrieved from Medion informational article.

Richardson, C. R. (1996). Quality control in feed production. The Center for Feed Industry Research and Education.

RICHI. (2025). Quality control rules for animal feed production process. Retrieved from customer guide.

All About Feed. (2022). An approach to quality control at the feed mill. Retrieved from industry publication.

KPH Feed Mill. (2025). The critical role of quality and control in animal feed production.

ISO 22000. (2024). Food safety management system standard. Retrieved from ISO overview.

Data Calculus content on quality control in feed manufacturing (2025). Quality control and assurance in animal feed manufacturing.